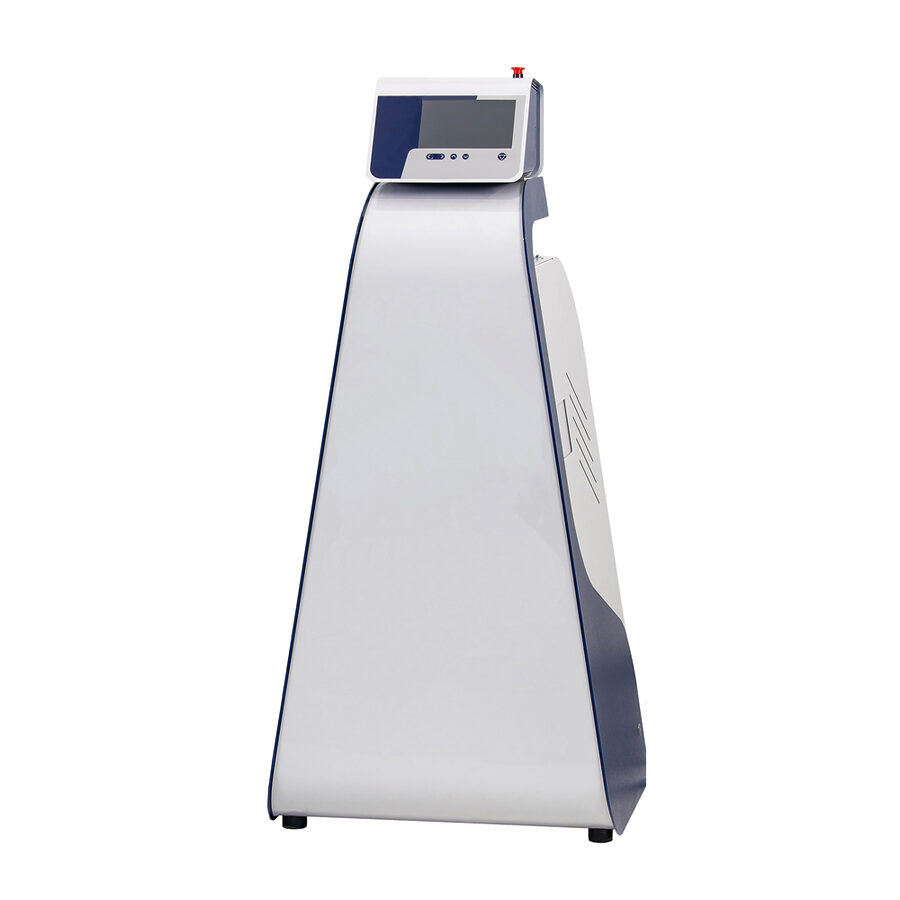

Triaxial test on rock specimens

This system is used to apply lateral pressure to rock samples with a maximum capacity of 70 Mpa.

The servo-controlled hydraulic group of the system allows to maintain a constant axial load and isotropic

pressure from 5 to 6 Mp.

The system control unit offers a real time reading of the pressure, fatigue and rupture values.The system automatically applies a constant pressure increase ranging between 0,5 and 10 MPa/sec, as established by international standards. In this way, it is capable of reaching breakage between 5 and 10 minutes of testing.

Combined with a set of strain gauges applied on the surface of the rock specimen, it is used for the automatic

reading in real time of different parameters such as:

-Poisson’s ratio

-Stress value between axial and radial strain

-Maximum break value

-Young’s modulus tangent and secant

-Maximum stress value in triaxial conditions

It is recommended the use of a compression load frame with capacity of 2000 or 3000 kN combined with the automatic servo-controlled system and with the automatic system for the Elastic Modulus on rocks AR300, that includes the data acquisition and processing software